Product Description

| Excavator hydraulic pump |

| Kubota35 Hitachi ZX27/30 Kobelco27 |

| |

| New, We produce ourselves |

| Displacement | 16+16mL/r (p1+p2) 6.4mL/r(p3)2.7mL/r(p4) |

| Rated pressure | 21MPa(p1+p2)20.6MPa(p3)3.9MPa(p4) |

| Ratedspeed(r/min) | 2300r/min |

| Direction of turning | Right-handed rotation |

| Net Weight | 25KG |

| TT bank transfer, Western Union,L/C |

| |

| Have in stock, within 3-5 days to ship out it |

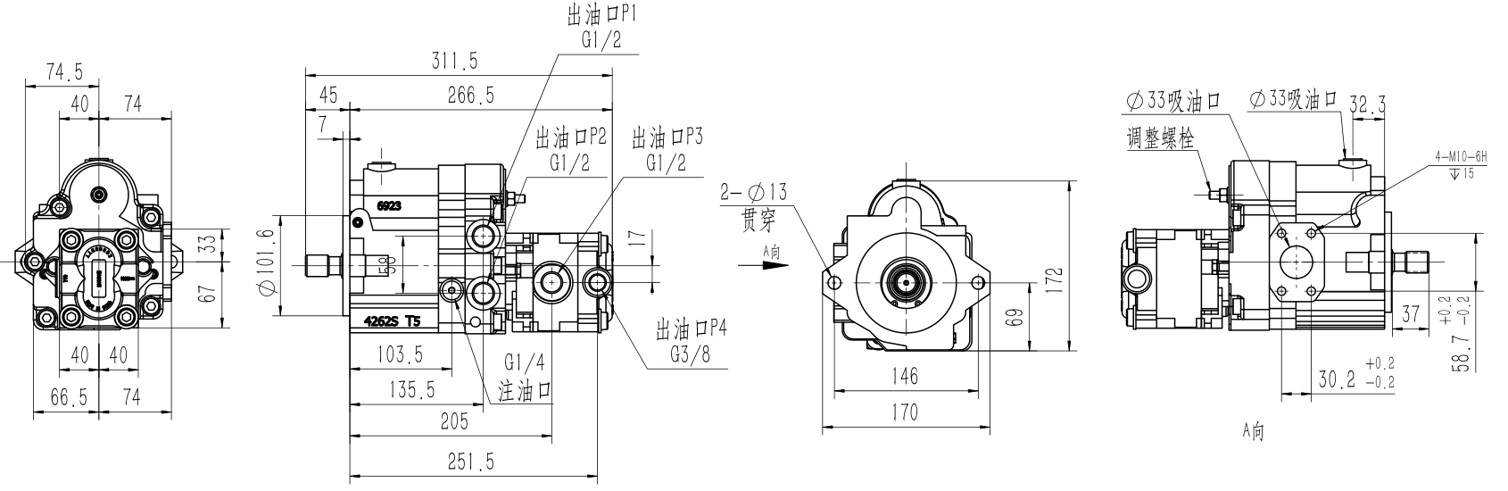

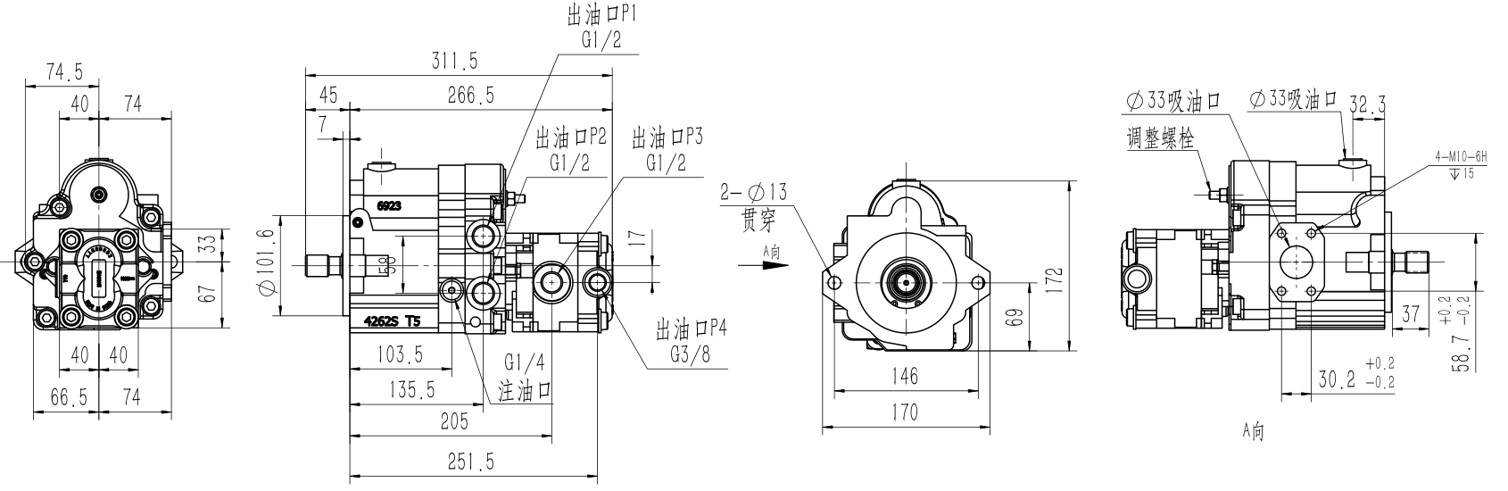

Product parameter diagram:

Product advantages and features

In the field of engineering construction, the excavator is an

indispensable and important tool, and its efficiency and

reliability are crucial to the smooth progress of the project.

However, these advantages cannot be separated from the core

component inside the excavator - the hydraulic pump. This article

will deeply reveal the product advantages and characteristics of

the excavator hydraulic pump, and show you its extraordinary charm

on the site.

First, efficient and excellent performance:

Stable output: The excavator hydraulic pump adopts advanced

variable displacement technology, which can intelligently adjust

the flow and pressure of the hydraulic system. Under different

working conditions, the pump can maintain a stable output to ensure

that the excavator is full of power and can efficiently complete

various tasks.

Rapid response: The hydraulic pump has a rapid response ability and

can provide the required hydraulic capacity in an instant, so that

the excavator can react quickly in emergency situations to ensure

the safety and efficiency of the project.

Second, excellent reliability and durability:

High quality materials: The hydraulic pump of the excavator is made

of high-strength alloy materials, which can effectively resist the

wear and corrosion caused by the harsh environment of the

construction site. These high-quality materials give the pump a

longer service life and lower maintenance costs.

Precision manufacturing: The hydraulic pump production process

adopts precision machining technology to ensure the accurate

manufacturing and assembly of parts, avoid leakage and failure

caused by improper assembly, and improve the reliability of the

product.

Third, intelligent control system:

Variable displacement technology: Modern excavator hydraulic pump

generally adopts variable displacement technology. This technology

allows the hydraulic pump to adjust its output in real time

according to the workload, ensuring optimal energy consumption and

thus reducing operating costs.

Fault diagnosis and prediction: The excavator hydraulic pump is

equipped with intelligent fault diagnosis and prediction function,

which can monitor the operating status of the pump in real time,

find potential faults in time and provide solutions. This helps

reduce downtime and increase productivity.

4. Energy saving and Environmental protection design:

Energy efficiency optimization: The application of variable

displacement technology enables the excavator hydraulic pump to

reduce energy consumption and reduce energy waste at low loads.

This helps to reduce the adverse impact on the environment and

meets the requirements of sustainable development.

Hydraulic oil recycling: Hydraulic pumps are designed with an

efficient oil circulation system that can effectively utilize

hydraulic oil and reduce oil consumption and emissions, thereby

reducing operating costs and environmental burdens.

Excavator hydraulic pump with high efficiency and excellent

performance, excellent reliability and durability, intelligent

control system, as well as energy saving and environmental

protection design, become the indispensable power source of

excavator efficient operation. Its excellent characteristics

provide a strong guarantee for the construction task of the

excavator, and play an important role in the field of modern

engineering construction. In the future, with the continuous

progress of technology, the excavator hydraulic pump will continue

to innovate and lead the new trend of development in the field of

construction machinery.

Product application range

Construction Projects:

Earthwork excavation: Hydraulic pumps of excavators play a vital

role in earthwork excavation. Through an intelligent hydraulic

control system, excavators are able to quickly and accurately

excavate earthworks of different shapes and depths, providing a

solid foundation for construction projects.

Foundation construction: In the foundation construction stage, the

hydraulic pump of the excavator is used to go deep into the

formation and dig the foundation. Its high efficiency and precise

control make the foundation construction more safe and reliable.

Ii. Mine Engineering:

Ore mining: In mining engineering, excavator hydraulic pump is

widely used in ore mining. Its powerful hydraulic power can easily

excavate and transport large amounts of ore, improving the

efficiency of mine mining.

Mine blasting: Hydraulic pump is used for mine blasting operation,

through intelligent adjustment of output, so that the excavator can

quickly clean up the debris after the ore is broken, and maintain

the continuity and efficiency of mine production.

Iii. Urban Construction:

Road construction: excavator hydraulic pump plays an important role

in urban road construction. It can excavate, lay and demolish roads

efficiently, providing strong support for urban traffic

construction.

Drainage engineering: Hydraulic pumps are widely used in urban

drainage engineering to help excavators achieve rapid drainage and

ensure the stable operation of urban drainage systems.

Iv. Agricultural field:

Irrigation projects: In the field of agriculture, excavator

hydraulic pumps are used in farmland irrigation projects to achieve

efficient and water-saving irrigation systems and improve

agricultural production efficiency.

Rural construction: In rural construction, hydraulic pumps are used

to dig and build rural roads, housing foundations, etc., to promote

the construction of rural infrastructure.

Technological advantage

In the field of modern construction and engineering, the efficient

operation of excavators cannot be separated from the key component

of hydraulic pump. The production technology advantages of

excavator hydraulic pump bring more excellent performance and

reliability to the excavator. This paper will deeply discuss the

production technology advantages of excavator hydraulic pump and

reveal its important position in excavator industry.

First, advanced manufacturing process:

Precision machining technology: The hydraulic pump production of

excavator adopts precision machining technology to ensure the

precise manufacturing of key components. Advanced CNC machine tools

and precision measuring equipment make the internal structure of

the hydraulic pump more fine, and the lubrication system is more

smooth, thereby improving the overall performance of the pump.

Advanced material selection: The application of high-strength alloy

materials makes the hydraulic pump of the excavator have better

wear resistance and corrosion resistance, and can run for a long

time under harsh conditions without damage. The use of these

materials also improves the durability of the pump, prolongs the

service life, and reduces the frequency and cost of maintenance.

Second, intelligent control technology:

Variable displacement technology: Variable displacement technology

is widely used in modern excavator hydraulic pumps. This technology

allows the pump to automatically adjust the output volume according

to operating conditions, ensuring efficient operation under

different load conditions. Through the precise adjustment of the

intelligent control system, the hydraulic pump can achieve the best

energy efficiency performance in different working conditions.

Fault diagnosis and prediction: The new generation of excavator

hydraulic pump is equipped with intelligent fault diagnosis and

prediction function, which can monitor the operating status of the

pump in real time and predict potential faults through data

analysis. This enables maintenance personnel to take measures in

advance to prevent faults and improve device reliability and

maintainability.

Third, energy saving and environmental protection design:

Energy efficiency optimization: Using variable displacement

technology, the excavator hydraulic pump can achieve intelligent

allocation of energy according to the working condition, avoiding

unnecessary energy waste. This helps to reduce the energy

consumption of excavators, reduce the negative impact on the

environment, and is in line with the development concept of energy

conservation and environmental protection.

Oil recycling: The technical advantage of excavator hydraulic pump

production lies in the design of an efficient oil circulation

system to reduce the waste of hydraulic oil. Through the recycling

of the oil, not only the consumption cost of the oil is reduced,

but also the pollution of the waste hydraulic oil to the

environment is reduced.

certificate

More products Show

If you have more needs, we can also provide you with customized

services, our products are under continuous development to ensure

the continuous needs of customers.

Our Services

Dear Customer,

Thank you for your interest and trust in our hydraulic walking

device products and services. We are a company specializing in the

production of high-quality hydraulic walking devices and have

accumulated years of experience and technical expertise in this

field. Our products are not only reliable in quality, but also

perform well in terms of performance, safety and durability.

Our service concept is customer-centric, with the goal of meeting

customer needs, adhering to the service philosophy of "integrity,

professionalism, efficiency, and innovation", and always

maintaining communication and exchange with customers to ensure

customer satisfaction and trust. Our team is composed of

experienced, skilled, and enthusiastic professionals who provide

customers with comprehensive service support, including:

1. Customization of products: We can provide customers with

customized hydraulic walking device products tailored to their

needs and requirements to ensure that the products meet the

customer's usage and environmental requirements.

2. Technical support: We have a professional technical team that

can provide customers with technical support for product selection,

installation and commissioning, maintenance and other aspects to

ensure that customers can use our products smoothly.

3. After-sales service: We provide 7x24-hour after-sales service to

ensure that customers can get timely solutions to any problems

encountered during use.

Our products have been exported to overseas markets and have won

unanimous praise from customers. We believe that through our

professional technology and high-quality services, we can become

your trusted long-term partner.

If you have any needs or questions about our products and services,

please feel free to contact us. We will provide you with the best

service and support and look forward to working with you!

Contact us

EMAIL:Bing83125@gmail.com

Whatsapp:8619554163292 8615805343909

FAQ

1, Q: Are you a manufacturer or a trading company? A: We are a manufacturer of quality final drives located in Qingdao

National High-Tech Industrial Development Zone with 14 years of

production experience .

2. Q: What is your company size ? A: Ours factory covers an area of 70,000 square meters with 120

employees . Turnover of 2019 is 20 million USD .

3, Q: What certificate do you have? A: ISO9001 / EN ISO 12100 / OHSAS 18001 / SGS

4, Q: How long is your delivery time? A: We keep stock for conventional products . New orders to produce

takes about 20 days. Customized products takes about 40 days .

5, Q: What kind of payment terms do you accept? A: T.T. / DP at sight / LC .

6, Q: What is your warranty policy? A: All our products are warranted for one full year from date of

delivery against defects in materials and workmanship.